Cutting processing

We use 4 lasers for cutting of which standards for processing guaranteed by the Company are as follows.

① Iron (SS400)…The maximum sheet thickness is 16mm.

② Stainless (SUS304)…The maximum sheet thickness is 12mm.

③ Aluminum (A5052)…The maximum sheet thickness is 12mm.

④ Brass…The minimum sheet thickness is 0.5mm.

⑤ Copper…The minimum sheet thickness is 0.5mm.

⑥ Acryl and wood…The maximum sheet thickness is 30mm.

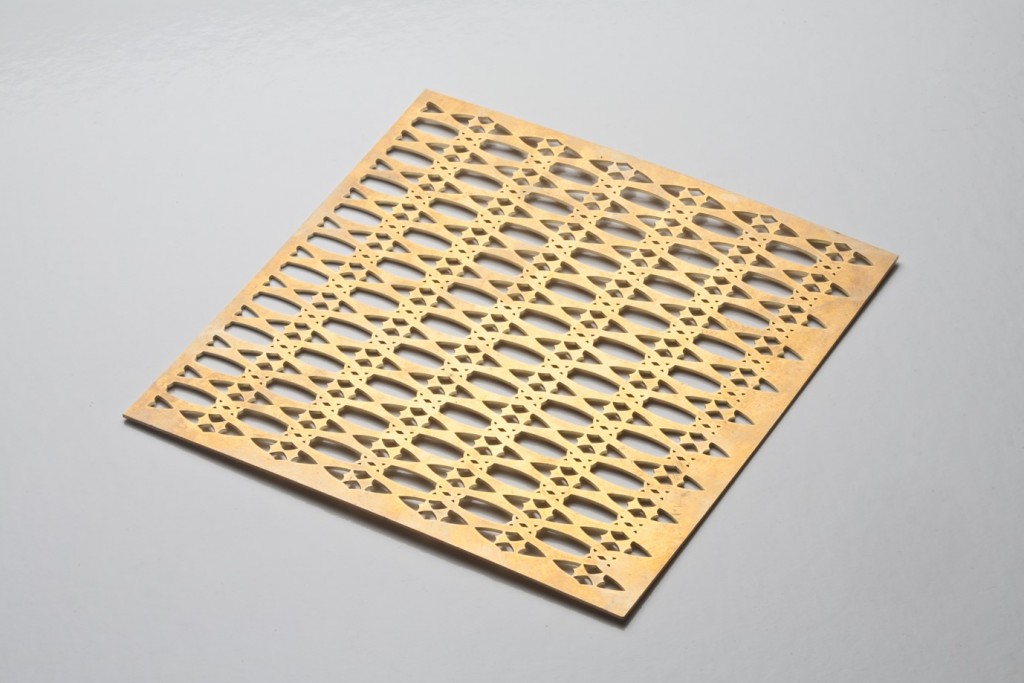

Object of a dragonfly made from aluminum, a sample of fine cutting processing by fiber laser (on the upper) and brass finely cut (on the bottom)

Main facilities

- TruLaser1030”, a fiber laser made by TRUMPF

- ML3015NX”, a CO2 laser processing machine made by Mitsubishi Electric

- ML3015HV2-R “, a CO2 laser processing machine made by Mitsubishi Electric

- Rooter SVH1325V

Samples of fine cutting processing by a fiber laser

- Object of a dragonfly (aluminum) on the right

- Finely cutting of brass